As an engineer, what gets you excited about your job? For most, it’s getting to work on really cool projects and innovating. Unfortunately, a good chunk of your time is wasted on other things, taking you away from the work you enjoy doing and the work that adds value for your company.

Research from Tech-Clarity’s Reducing Non-Value Added Work in Engineering reveals that engineers waste a startling 32% on non-value-added work. That’s a lot of lost opportunity. Imagine what you could do if you could get almost a third of your time back?

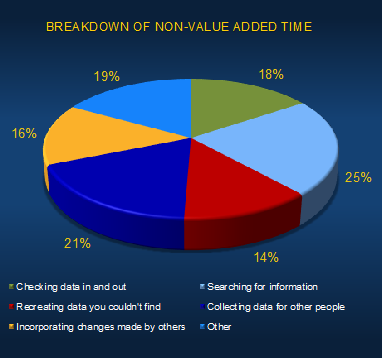

First, where does all this non-value-added work come from? The research identifies the many tasks that contribute to it.

As you can see from the graph, much of this non-value-added work is related to the many manual tasks associated with managing, sharing, and finding data. Data tends to be stored in multiple places, so there is no single source of truth.

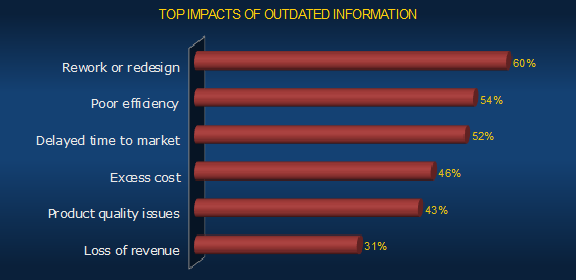

Without a single source of truth, there is no traceability across the data. It then becomes practically impossible to identify the impact of an update to requirements, new design work, or changes to other parts of the design. Without traceability, changes can not automatically propagate across all product data. Instead, changes and updates become a very manual, if not impossible, process to identify everything that is impacted and update it. This is further complicated if the same data is located in multiple places. The situation creates a significant risk for outdated and conflicting data. Unfortunately, this costs the company in numerous ways, as seen in the graph.

Without a single source of truth, there is no traceability across the data. It then becomes practically impossible to identify the impact of an update to requirements, new design work, or changes to other parts of the design. Without traceability, changes can not automatically propagate across all product data. Instead, changes and updates become a very manual, if not impossible, process to identify everything that is impacted and update it. This is further complicated if the same data is located in multiple places. The situation creates a significant risk for outdated and conflicting data. Unfortunately, this costs the company in numerous ways, as seen in the graph.

When design work is based on outdated information, errors will be inevitable. These errors result in costly rework and redesign. Wasting even more time to correct these problems means poor efficiency which can delay time to market. As the design nears completion, there are fewer options to fix problems, so errors become much more expensive and time-consuming to fix. Plus, with limited options, solutions may be less than ideal, which will hurt product quality or drive up the cost. Of course, if problems are missed entirely, there will be even bigger quality problems in the field. The combination of poor quality, higher cost, and late to market all hurt competitiveness which can reduce revenue opportunities.

This problem gets even worse when multiple engineering disciplines are involved. When products integrate mechanical components, electronics, and embedded software, there are inherent silos. Each engineering discipline uses its own tools, tailored for that discipline, so typically the data is stored separately. Consequently, each discipline has minimal visibility into what others are doing. The numerous interdependencies across disciplines make this extremely problematic. The problems impact every stage of development from requirements, through development, to tests. Different configurations add further complexity. Overall, this situation will become harder and harder to manage without a better solution in place.

This problem gets even worse when multiple engineering disciplines are involved. When products integrate mechanical components, electronics, and embedded software, there are inherent silos. Each engineering discipline uses its own tools, tailored for that discipline, so typically the data is stored separately. Consequently, each discipline has minimal visibility into what others are doing. The numerous interdependencies across disciplines make this extremely problematic. The problems impact every stage of development from requirements, through development, to tests. Different configurations add further complexity. Overall, this situation will become harder and harder to manage without a better solution in place.

While many companies realize a single source of truth is ideal, they often don’t think it is feasible for their business. Many believe it can only be achieved with a “rip and replace” strategy which requires ripping out every software solution they have and investing in a new single solution. While there are business benefits to consolidating IT solutions, this may not be ideal for every company. For many, not only would it be extremely costly, it would be far too disruptive to the business.

For these companies, the ideal solution is to link all the different sources of data with a single digital thread. This means the data stays where it is. Engineers continue to work with the tools they are comfortable with so their workflows are not disrupted. The difference is that they can now access all data types from a single access point. They have traceability so they can quickly identify the impact of a change and also have visibility to changes made by others that impact them. They are no longer wasting time searching or collecting data because they can access it from a single location. They don't have to worry about outdated data because the digital thread keeps it synchronized.

For these companies, the ideal solution is to link all the different sources of data with a single digital thread. This means the data stays where it is. Engineers continue to work with the tools they are comfortable with so their workflows are not disrupted. The difference is that they can now access all data types from a single access point. They have traceability so they can quickly identify the impact of a change and also have visibility to changes made by others that impact them. They are no longer wasting time searching or collecting data because they can access it from a single location. They don't have to worry about outdated data because the digital thread keeps it synchronized.

While there is clearly a lot of benefit to this type of integration, it can be difficult to achieve. This is why industry standards are so important. Standards provide a common definition that makes integration much easier. Plus, because it is an industry-standard, you shouldn’t have to worry about breaking the integration each time you upgrade your software. In addition, industry standards have been proven and take advantage of best practices. Consequently, there can be a significant benefit to using software vendors who adopt or support standards. Open Services for Lifecycle Collaboration (OSLC) is such a standard and is a leading way to connect applications such as Application Lifecycle Management (ALM), Product Lifecycle Management (PLM), and other applications to create a digital thread for your product data. A vendor who supports OSLC should not only enable a more seamless, faster integration but will also help to future-proof your solution.

While there is clearly a lot of benefit to this type of integration, it can be difficult to achieve. This is why industry standards are so important. Standards provide a common definition that makes integration much easier. Plus, because it is an industry-standard, you shouldn’t have to worry about breaking the integration each time you upgrade your software. In addition, industry standards have been proven and take advantage of best practices. Consequently, there can be a significant benefit to using software vendors who adopt or support standards. Open Services for Lifecycle Collaboration (OSLC) is such a standard and is a leading way to connect applications such as Application Lifecycle Management (ALM), Product Lifecycle Management (PLM), and other applications to create a digital thread for your product data. A vendor who supports OSLC should not only enable a more seamless, faster integration but will also help to future-proof your solution.

The result is more time for value-added work for engineers. Engineers can spend more of their time doing the work they enjoy and focus on developing better products. The resulting quality, innovation, and lower cost mean the company will benefit from more competitive products.

The result is more time for value-added work for engineers. Engineers can spend more of their time doing the work they enjoy and focus on developing better products. The resulting quality, innovation, and lower cost mean the company will benefit from more competitive products.

About the Author:

Michelle Boucher is the Vice President of Research for Engineering Software at research firm Tech-Clarity. Ms. Boucher has spent over 25 years in various roles in engineering, marketing, and management, working in the industry as well as software vendors. She has spent the last 10 years as an industry analyst researching the business value of improvements to product development.

Michelle Boucher is the Vice President of Research for Engineering Software at research firm Tech-Clarity. Ms. Boucher has spent over 25 years in various roles in engineering, marketing, and management, working in the industry as well as software vendors. She has spent the last 10 years as an industry analyst researching the business value of improvements to product development.

She has benchmarked over 7000 product development professionals and published over 90 reports on product development best practices. She graduated magna cum laude with an MBA from Babson College and earned a BS in Mechanical Engineering, with distinction, from Worcester Polytechnic Institute.

.png)

%203.png?width=251&height=69&name=SWC18002-BrndStndrds_Logo_mech_RGB_2%20(2)%203.png)

Leave us your comment